Barcode Generator: Ever wondered how those little lines and squares on everything from groceries to shipping boxes actually work? It’s way more interesting than you think! This deep dive explores the world of barcode generators, from the different types and their underlying mechanics to the software, APIs, and security considerations involved. We’ll cover everything from basic linear barcodes to the more complex 2D QR codes, exploring how they’re used across various industries and the future of this essential technology.

We’ll break down the nitty-gritty of barcode generation, covering different software features, API integrations, image optimization techniques, and even security vulnerabilities. Get ready to level up your understanding of this ubiquitous technology!

Barcode Generator Types

Choosing the right barcode generator depends heavily on your needs. Different barcode types offer varying levels of data storage capacity and error correction, making some better suited for certain applications than others. Understanding these differences is key to selecting the appropriate tool for your project.

Barcode Generator Types Comparison

This table compares some common barcode types, highlighting their strengths and weaknesses.

| Type | Description | Applications | Strengths & Weaknesses |

|---|---|---|---|

| QR Code (Quick Response Code) | A two-dimensional barcode capable of storing significantly more data than linear barcodes. | Website URLs, contact information, product details, event tickets, payment information. | Strengths: High data capacity, error correction, easy to scan. Weaknesses: Can be visually cluttered with large amounts of data, requires a 2D scanner. |

| UPC-A (Universal Product Code – A) | A linear barcode commonly used in the United States and Canada for tracking retail products. | Grocery items, consumer packaged goods, retail inventory management. | Strengths: Widely recognized and supported, simple to implement. Weaknesses: Limited data capacity, susceptible to errors if damaged. |

| EAN-13 (European Article Number – 13) | A linear barcode similar to UPC-A, but used internationally. | Global retail product tracking, inventory management. | Strengths: International standardization, widely accepted. Weaknesses: Limited data capacity, susceptible to errors if damaged. |

Linear Barcode Generator Internal Workings

A linear barcode generator takes input data, typically a numerical identifier, and transforms it into a visual representation of alternating bars and spaces. This process involves several steps: First, the input data is encoded using a specific algorithm determined by the barcode symbology (e.g., UPC-A, EAN-13). This algorithm assigns specific patterns of bars and spaces to the digits in the data.

Next, the encoded data is formatted to include checksum digits for error detection. Finally, the generator outputs a visual representation of the encoded data, which can then be printed or displayed. The precise algorithm used differs depending on the chosen barcode symbology, each having a defined structure and encoding rules to ensure accurate reading. For example, UPC-A uses a specific arrangement of bars and spaces for each digit, and the overall structure includes a start and stop pattern.

1D vs. 2D Barcode Generators

The key difference between 1D and 2D barcode generators lies in their data storage capacity and the way they encode information. 1D barcode generators, such as those producing UPC-A or EAN-13, store data linearly, using a series of bars and spaces to represent numerical data. They have a relatively low data storage capacity. 2D barcode generators, like QR code generators, encode data in two dimensions, using both horizontal and vertical patterns.

This allows for significantly greater data storage capacity and the inclusion of alphanumeric characters, images, and even URLs. Furthermore, 2D barcodes often incorporate error correction, making them more resilient to damage. The increased data capacity of 2D barcodes makes them suitable for applications requiring more complex information, while 1D barcodes are well-suited for simple product identification.

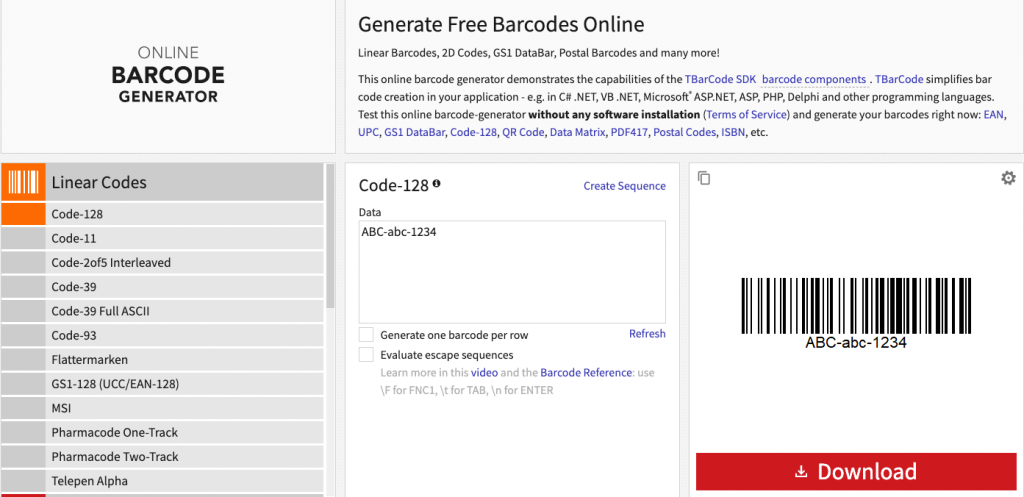

Barcode Generator Software Features

Choosing the right barcode generator software depends heavily on its features. A robust application offers a range of functionalities beyond simple barcode creation, impacting both efficiency and the quality of the final product. Understanding these features is crucial for selecting a tool that meets your specific needs.

Many barcode generator software packages offer a variety of features designed to streamline the process and enhance the output. These range from basic functionalities like selecting barcode symbologies to more advanced options like batch processing and integration with other software.

Essential Features of Barcode Generator Software

The following features are commonly found in popular barcode generator software and represent key considerations when making a selection. The presence or absence of these features significantly impacts usability and functionality.

- Barcode Symbology Support: The software should support a wide range of barcode symbologies, including common types like UPC-A, EAN-13, Code 128, QR Code, and Data Matrix. The more symbologies supported, the more versatile the software.

- Data Input Methods: Flexible data input options are essential. The software should allow for manual data entry, importing data from spreadsheets (CSV, XLSX), or databases, and potentially integrating with other systems via APIs.

- Customization Options: Customization options are crucial for branding and compliance. These include adjusting barcode size, adding text or logos, choosing colors, and selecting the output format (e.g., PNG, JPG, SVG, PDF).

- Batch Processing: For high-volume barcode generation, batch processing is a must-have. This feature allows users to generate hundreds or thousands of barcodes at once from a single data source, significantly increasing efficiency.

- Output Format Options: The ability to export barcodes in various formats (PNG, JPG, SVG, PDF, etc.) is essential for compatibility with different printing methods and applications. Support for vector formats (like SVG) ensures scalability without loss of quality.

- Integration Capabilities: Integration with other software systems (e.g., ERP, CRM, inventory management systems) is crucial for seamless workflow integration. This often involves APIs or other data exchange mechanisms.

- Error Correction: Some barcode symbologies offer error correction capabilities. The software should allow users to leverage these features to ensure barcode readability even if partially damaged.

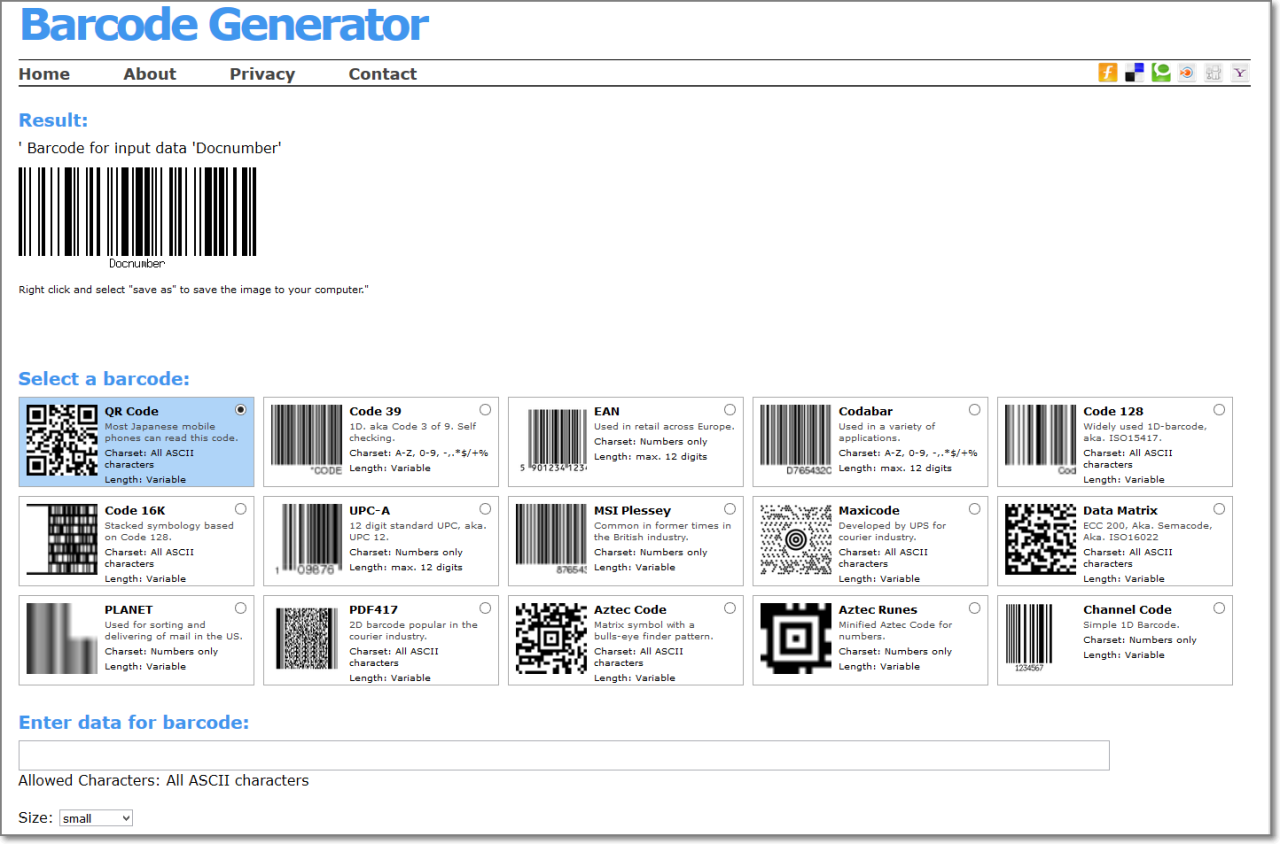

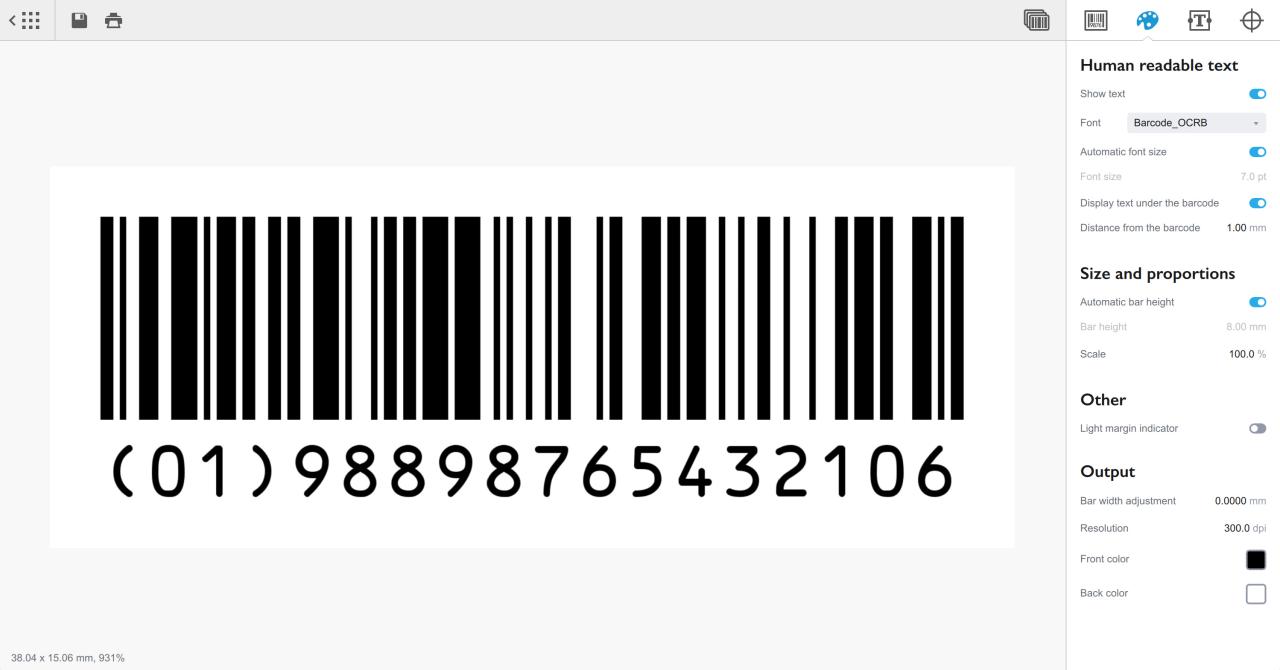

User Interface Mockup

A simple barcode generator application might feature a clean and intuitive user interface. Imagine a layout with distinct sections for data input, barcode settings, and output preview. The data input section could include a field for manual entry or a file upload option for importing data from a spreadsheet. The barcode settings section would allow users to select the barcode symbology, adjust the size and dimensions, and add any text or logos.

A preview pane would display a real-time rendering of the generated barcode, allowing users to fine-tune settings before generating the final output.

The main window would be divided into three primary sections. The left section would house the data input field, allowing users to either manually type in data or import a CSV file. The central section would contain options to select the barcode type (e.g., UPC-A, EAN-13, Code 128), adjust the barcode height and width, and add any necessary text or logos.

Finally, the right section would display a live preview of the generated barcode, dynamically updating as users change the settings.

Barcode Generator Software Pricing Models

Pricing models for barcode generator software vary widely, depending on the features offered, the number of barcodes generated, and the licensing terms. Understanding these models is crucial for budgeting and selecting a cost-effective solution.

| Pricing Model | Description | Example |

|---|---|---|

| One-time Purchase | A single upfront payment grants perpetual access to the software. | A basic barcode generator might cost $50-$100. |

| Subscription | Recurring monthly or annual payments for access to the software and its features. Often includes updates and support. | A cloud-based barcode generator might cost $10-$50 per month. |

| Per-Barcode Pricing | Users pay a fee for each barcode generated. This model is often used for high-volume barcode generation. | The cost might range from a few cents to a dollar per barcode. |

| Tiered Pricing | Different pricing tiers offer varying levels of features and usage limits. | A software might offer a free tier with limited features and paid tiers with increased functionality and barcode generation limits. |

Barcode Generator API Integration

Integrating a barcode generator API into your application offers a streamlined way to generate barcodes without the hassle of managing the underlying barcode generation libraries and logic. This allows developers to focus on their core application functionality rather than getting bogged down in the intricacies of barcode creation. However, there are potential challenges to consider, such as API reliability, cost, and potential limitations in customization.API integration simplifies barcode generation, allowing for seamless integration into various applications.

This approach offers several benefits, including reduced development time and improved efficiency. The main challenge lies in selecting a reliable and suitable API, managing potential errors, and understanding the API’s rate limits and pricing structure.

API Integration Examples

Below are code snippets illustrating how to integrate a hypothetical barcode generator API into applications using Python and JavaScript. These examples assume a RESTful API with endpoints for generating various barcode types. Remember to replace `”YOUR_API_KEY”` and the endpoint URL with your actual credentials and API endpoint.

Python Example:

import requests

api_key = "YOUR_API_KEY"

url = "https://api.example.com/generate_barcode"

data =

"type": "EAN13",

"data": "1234567890128",

"apiKey": api_key

response = requests.post(url, json=data)

if response.status_code == 200:

barcode_data = response.json()

print(f"Barcode generated successfully: barcode_data['barcode']")

else:

print(f"Error generating barcode: response.status_code - response.text")

JavaScript Example:

const apiKey = "YOUR_API_KEY";

const url = "https://api.example.com/generate_barcode";

const data =

type: "QR",

data: "https://www.example.com",

apiKey: apiKey

;

fetch(url,

method: "POST",

headers:

"Content-Type": "application/json"

,

body: JSON.stringify(data)

)

.then(response =>

if (!response.ok)

throw new Error(`HTTP error! status: $response.status`);

return response.json();

)

.then(data =>

console.log("Barcode generated successfully:", data.barcode);

)

.catch(error =>

console.error("Error generating barcode:", error);

);

Error Handling in API Calls

Robust error handling is crucial for a reliable barcode generation process. The examples above demonstrate basic error checking by inspecting the HTTP status code returned by the API. A status code of 200 (OK) indicates success, while other codes (e.g., 400 Bad Request, 500 Internal Server Error) signify errors. More sophisticated error handling might involve:

- Specific error codes from the API documentation for more detailed diagnosis.

- Retry mechanisms for transient errors (e.g., network issues).

- Logging error details for debugging and monitoring.

- User-friendly error messages to the application’s end-users.

For example, a 400 Bad Request might indicate invalid input data, while a 500 Internal Server Error suggests a problem on the API server side. Appropriate handling of these scenarios is vital for a user-friendly and reliable application. A well-designed error handling system will gracefully handle unexpected situations and provide informative feedback to both the developer and the end-user.

Barcode Image Optimization: Barcode Generator

Creating high-quality barcode images is crucial for successful scanning. Poorly optimized images can lead to read errors, wasted time, and ultimately, frustrated users. This section will cover key techniques for optimizing barcode image resolution and size, and discuss the impact of different image formats on scannability.

Optimizing barcode images involves balancing resolution, file size, and print quality to ensure reliable scanning across various media. High-resolution images are generally preferred for print, but unnecessarily large file sizes can slow down processing and increase storage needs. Conversely, images that are too small or low-resolution may contain insufficient detail for accurate scanning.

Resolution and Size Optimization

The optimal resolution for a barcode depends heavily on the printing method and the scanning distance. For example, a barcode printed on a shipping label intended for a handheld scanner at close range may only require a resolution of 150-200 DPI (dots per inch). However, a barcode printed on a smaller item, like a product tag, might require a higher resolution of 300 DPI or more to ensure readability at typical scanning distances.

Larger barcodes, printed at a lower DPI, generally require less file space. The key is to find the balance between readability and file size. Experimentation with different resolutions and observing scan rates is recommended.

Impact of Image Formats

Different image formats affect barcode readability and file size.

PNG (Portable Network Graphics) is a lossless format, meaning it preserves all image data without compression artifacts. This is generally ideal for barcodes, as it ensures the sharp lines and precise dimensions necessary for accurate scanning. However, PNG files can be larger than other formats.

SVG (Scalable Vector Graphics) is a vector format, meaning it uses mathematical equations to define the image, rather than pixels. This allows SVG barcodes to be scaled to any size without losing quality. This is particularly beneficial for applications requiring barcodes at various sizes. However, not all barcode scanners support SVG.

JPEG (Joint Photographic Experts Group) is a lossy format, meaning it compresses the image by discarding some data. While this leads to smaller file sizes, it can introduce artifacts that may interfere with barcode scanning. JPEG is generally not recommended for barcodes due to potential loss of detail.

Best Practices for Barcode Scannability

To ensure consistent and reliable barcode scanning, adhere to these best practices:

- Use high-contrast colors: A dark barcode on a light background (or vice-versa) maximizes contrast and improves readability. Avoid subtle color variations.

- Maintain correct aspect ratio: Do not distort the barcode; maintain its original proportions to prevent scanning errors.

- Ensure sufficient quiet zone: The quiet zone is the blank space surrounding the barcode. Adequate quiet zones are essential for proper barcode recognition. Industry standards define the minimum required quiet zone size. Failing to provide sufficient quiet zone is a major source of scanning failures.

- Avoid image noise and distortion: Blurred or distorted barcodes are difficult to scan. Use high-quality printing methods and avoid printing on textured surfaces that might obscure the barcode.

- Validate barcode symbology: Use the correct symbology (e.g., EAN, UPC, Code 128) for the intended application and scanner type. Ensure that the generated barcode conforms to the relevant standards.

Following these guidelines significantly improves the likelihood of successful barcode scans, reducing errors and increasing efficiency.

Security Considerations for Barcode Generators

Barcode generators, while seemingly simple tools, present several security vulnerabilities if not carefully designed and implemented. The integrity of the data encoded within a barcode, and the system’s resistance to manipulation, are crucial for maintaining trust and preventing fraud. This section explores potential weaknesses and mitigation strategies.

The primary concern revolves around the potential for data manipulation and counterfeiting. Malicious actors could alter barcode data to reflect incorrect pricing, product information, or even redirect shipments. This can lead to significant financial losses, supply chain disruptions, and reputational damage for businesses.

Data Manipulation Prevention

Preventing data manipulation requires a multi-faceted approach. Robust error detection and correction mechanisms, incorporated during barcode generation, are essential. This involves using checksums or other redundancy techniques that can identify if a barcode has been tampered with. Furthermore, employing strong encryption techniques protects the underlying data from unauthorized access or modification. Regular audits and validation of generated barcodes against a trusted database can also help detect anomalies and prevent fraudulent activity.

Implementing access controls to the barcode generation system itself, restricting access only to authorized personnel, further minimizes the risk of malicious alterations.

Counterfeiting Prevention

Counterfeiting involves creating fraudulent barcodes that mimic legitimate ones. This is often achieved through sophisticated printing techniques or digital manipulation. Several strategies can help mitigate this threat. One approach is the use of advanced barcode symbologies, like those incorporating sophisticated error correction codes or unique identifiers. Another critical element is integrating security features directly into the barcode’s design, such as micro-printing or specialized inks that are difficult to replicate.

Combining this with physical security measures, such as tamper-evident packaging, adds another layer of protection against counterfeiting. Watermarking the barcode image with a unique digital signature, which can be verified upon scanning, provides another strong deterrent.

Data Encryption Techniques

Data encryption plays a crucial role in securing sensitive information encoded within barcodes. While barcodes themselves don’t directly support encryption, the databefore* encoding can be encrypted using various methods. Symmetric encryption algorithms, like AES (Advanced Encryption Standard), offer strong encryption with relatively fast processing speeds. These algorithms use a single secret key for both encryption and decryption.

Alternatively, asymmetric encryption, using algorithms like RSA, employs a pair of keys – a public key for encryption and a private key for decryption – providing added security for data transmission and storage. The choice of encryption algorithm depends on the specific security requirements and the sensitivity of the data being encoded. For instance, a high-security application requiring protection against sophisticated attacks would benefit from AES-256 encryption with strong key management practices.

A less sensitive application might use a simpler algorithm, but proper key management remains crucial regardless of the chosen algorithm.

Barcode Generator Use Cases

Barcode generators are ubiquitous tools impacting various sectors, streamlining operations and enhancing data management. Their applications span from everyday retail transactions to complex supply chain logistics and precise healthcare administration. Understanding these use cases highlights the versatility and significant impact of barcode technology.

Barcode generators offer a powerful way to improve efficiency and accuracy in data management across numerous industries. By automating data entry and minimizing human error, businesses can significantly reduce costs and improve productivity. The resulting improvements in inventory management, tracking, and overall operational efficiency contribute to a significant competitive advantage.

Barcode Generator Applications Across Industries

The widespread adoption of barcode technology is a testament to its effectiveness. Here are some key examples of how barcode generators are used in different sectors:

- Retail: Retailers use barcode generators to create unique identifiers for each product, enabling efficient inventory management, point-of-sale transactions, and loss prevention. Scanning barcodes at checkout speeds up the process and minimizes errors in pricing and item identification. This allows for better stock control, preventing stockouts and overstocking.

- Logistics and Supply Chain: In logistics, barcodes track packages and goods throughout the entire supply chain, from manufacturing to delivery. This ensures accurate tracking, reducing delays and improving delivery times. Real-time tracking capabilities enable proactive management of shipments, preventing losses and optimizing routes.

- Healthcare: Healthcare providers utilize barcode generators to identify patients, track medical supplies, and manage medications. This helps to prevent medication errors, improve patient safety, and streamline administrative processes. Barcodes on medical devices can also help in tracking their use and maintenance.

- Manufacturing: Barcode generators are essential for tracking components, managing inventory, and monitoring production processes. They ensure accurate tracking of materials, reducing waste and optimizing production efficiency. This can lead to improved quality control and reduced production costs.

Case Study: Barcode Generators in Retail

Consider a large grocery chain implementing a new barcode generation system. Previously, manual data entry for new products was time-consuming and prone to errors. The new system automates barcode generation, directly linking product information (name, price, description) to the barcode. This resulted in:

- A 75% reduction in data entry errors.

- A 50% decrease in time spent on product onboarding.

- Improved inventory accuracy, leading to less waste and better stock management.

- Enhanced customer experience through faster checkout processes.

The return on investment was significant, demonstrating the clear benefits of integrating efficient barcode generation into core business operations.

Improved Efficiency and Accuracy in Data Management

Barcode generators fundamentally transform data management by automating processes that were previously manual and error-prone. The speed and accuracy of barcode scanning compared to manual data entry lead to several key improvements:

- Reduced Data Entry Errors: Manual data entry is inherently susceptible to human error. Barcode scanning eliminates this risk, ensuring data accuracy.

- Increased Efficiency: Scanning barcodes is significantly faster than manual data entry, speeding up processes across various departments.

- Improved Inventory Management: Real-time tracking of inventory levels provides valuable insights into stock levels, allowing for better forecasting and reduced waste.

- Enhanced Traceability: Barcodes enable complete traceability of products throughout their lifecycle, improving supply chain transparency and accountability.

Barcode Symbologies and Standards

Picking the right barcode symbology is crucial for a successful application. Different symbologies offer varying levels of data density, error correction, and readability, making the choice dependent on the specific needs of the project. Understanding the nuances of each symbology is key to optimizing your barcode system.

Barcode symbologies are essentially different ways of representing data visually as a series of bars and spaces. Each symbology has its own set of characteristics, making some better suited for certain applications than others. Choosing the wrong symbology can lead to scanning errors, inefficiencies, and ultimately, project failure. This section will break down the most common symbologies and their applications.

Barcode Symbology Comparison

The following table compares several common barcode symbologies, highlighting their strengths and weaknesses.

| Symbology | Description | Applications | Encoding Standard |

|---|---|---|---|

| UPC-A | 12-digit barcode used primarily for retail products in North America. | Grocery stores, retail, product identification. | ISO/IEC 15417 |

| EAN-13 | 13-digit barcode, the international equivalent of UPC-A. | Global retail, product identification. | ISO/IEC 15417 |

| Code 39 | Alphanumeric symbology; relatively low density but widely compatible. | Inventory management, asset tracking, libraries. | ISO/IEC 16388 |

| Code 128 | High-density alphanumeric symbology; supports a wide range of characters. | Logistics, warehousing, supply chain management. | ISO/IEC 15417 |

| Data Matrix | 2D symbology, capable of encoding large amounts of data in a small space. | Pharmaceutical tracking, automotive parts, asset management. | ISO/IEC 16022 |

| QR Code | 2D symbology, highly versatile and capable of encoding various data types, including URLs. | Marketing, ticketing, access control. | ISO/IEC 18004 |

| PDF417 | 2D symbology; high capacity and error correction. | Government IDs, transportation documents, ticketing. | ISO/IEC 15438 |

Key Differences Between Barcode Standards

Different barcode standards dictate the structure, encoding, and error correction capabilities of a symbology. Compliance with these standards ensures interoperability and reliable scanning across various systems. For instance, the difference between UPC-A and EAN-13 lies primarily in the number of digits and their intended geographic use. Code 128 offers significantly higher data density than Code 39, making it ideal for applications requiring more information to be encoded in a smaller space.

2D symbologies like Data Matrix and QR codes differ dramatically from 1D symbologies in their ability to store significantly more data and incorporate error correction features. The choice of standard is driven by the application’s specific requirements.

Selecting the Appropriate Barcode Symbology, Barcode generator

Choosing the right barcode symbology involves considering several factors. The amount of data to be encoded is paramount; high-density symbologies like Code 128 or 2D symbologies are necessary for large datasets. The required level of error correction is another key consideration; applications in harsh environments might benefit from symbologies with robust error correction. Readability is crucial; some symbologies are more tolerant to damage or poor print quality than others.

Finally, the availability of scanning equipment and software compatibility should be taken into account. For example, a retail environment might prioritize UPC-A or EAN-13 due to widespread scanner compatibility, while a pharmaceutical application might opt for Data Matrix due to its high data density and error correction capabilities.

Generating Barcodes from Databases

Dynamically generating barcodes directly from a database is super efficient for applications needing a large volume of unique barcodes, like inventory management systems or e-commerce platforms. This approach eliminates the need for manual barcode creation, reducing errors and saving tons of time. Instead of pre-generating barcodes, they’re created on demand, pulling data directly from your database.Integrating a barcode generator with a database management system (DBMS) usually involves using a programming language (like Python or PHP) to connect to the database, fetch relevant data, and then use a barcode generation library to create the barcode image.

This process can be seamlessly integrated into existing workflows, whether it’s printing labels, generating reports, or updating an online inventory.

Database Connection and Data Retrieval

Connecting to a database and retrieving the data needed for barcode generation is the first step. This involves establishing a connection using the appropriate database driver and then executing a query to select the necessary data fields. The specific implementation depends on the database system (MySQL, PostgreSQL, etc.) and the programming language being used. For example, a Python script using the `mysql.connector` library might look something like this:“`pythonimport mysql.connectorimport barcodemydb = mysql.connector.connect( host=”localhost”, user=”yourusername”, password=”yourpassword”, database=”yourdatabase”)mycursor = mydb.cursor()mycursor.execute(“SELECT product_id, product_name FROM products”)myresult = mycursor.fetchall()for x in myresult: ean = barcode.get_barcode_class(‘ean13’) ean_barcode = ean(str(x[0]), writer=barcode.writer.ImageWriter()) ean_barcode.save(str(x[0])) # Saves barcode image as product_id.png“`This example retrieves product IDs and names.

The product ID is used to generate an EAN-13 barcode, and the image is saved with the product ID as the filename. Remember to replace placeholders like “yourusername,” “yourpassword,” and “yourdatabase” with your actual credentials. Error handling and more robust data validation should be added for production environments.

Barcode Generation and Image Handling

Once the data is retrieved, a barcode generation library is used to create the barcode image. Many libraries are available, offering various barcode symbologies (like EAN, UPC, Code 128, etc.). The generated image is then typically saved to a file or streamed directly to the output, depending on the application’s needs. Libraries like Python’s `barcode` library simplify this process.

The example above already shows how to use it to generate and save an EAN-13 barcode. Different libraries will have slightly different APIs, but the general principle remains the same: fetch data, generate barcode, and handle the resulting image.

Integration with Existing Systems

Integrating this functionality into existing systems requires careful planning and consideration of the overall architecture. The barcode generation process can be incorporated into existing applications or web services through APIs or scheduled tasks. For example, a web application could generate barcodes on demand when a new product is added to the database, or a scheduled task could generate barcodes for all products in the database on a regular basis.

The key is to design a system that efficiently handles the barcode generation process without impacting the performance of other system components. Careful consideration of database transaction management is crucial to ensure data consistency and integrity.

Barcode Generator Error Handling

Generating barcodes seems straightforward, but a surprising number of things can go wrong. From dodgy data input to unexpected system hiccups, robust error handling is crucial for a reliable barcode generator. A well-designed system anticipates potential problems and provides informative feedback, preventing frustrating user experiences and ensuring data integrity.Error handling in a barcode generator focuses on gracefully managing situations where the input data is invalid, the barcode generation process fails, or unexpected system issues arise.

This involves identifying the error, providing a clear and helpful error message to the user, and, ideally, suggesting corrective actions. The ultimate goal is to create a system that’s resilient and prevents data loss or corrupted barcodes.

Invalid Data Input Errors

Invalid data input is a frequent source of errors. This can include incorrect character sets, data exceeding the barcode symbology’s length limits, or simply empty input fields. For example, attempting to encode alphanumeric data into a barcode symbology that only supports numeric data will result in an error. Effective error handling involves validating the input databefore* attempting barcode generation.

This validation should check data type, length, and character set against the chosen symbology’s specifications. A well-structured validation process will pinpoint the exact location and nature of the invalid data, providing the user with specific instructions for correction. The system should clearly indicate which field contains the error and what the acceptable format is.

Barcode Generation Errors

Even with valid input data, barcode generation can fail due to various reasons. This could stem from issues with the barcode generation library, insufficient system resources, or problems writing the generated barcode to a file or database. A robust system will implement comprehensive exception handling mechanisms to catch these errors. These mechanisms should log the error details for debugging purposes, and provide a user-friendly message explaining the failure without revealing sensitive technical information.

For instance, instead of displaying a cryptic error code, a helpful message might state, “Barcode generation failed. Please check your system resources or try again later.” The system should also include a mechanism for retrying the generation process or escalating the error to a system administrator.

Unexpected System Errors

Unexpected system errors, such as disk space issues or network connectivity problems, can interrupt the barcode generation process. These errors require a different approach than data input or generation errors. The system should gracefully handle these exceptions, perhaps by temporarily suspending the operation and providing the user with a message indicating the problem and suggesting a resolution (e.g., “Network connection lost.

Please check your network and try again”). Implementing proper logging mechanisms is vital here to track the frequency and nature of these system errors, aiding in identifying and resolving underlying system issues. Furthermore, implementing retry mechanisms with exponential backoff can enhance the system’s resilience to temporary network glitches.

Improving Robustness and Reliability

Several strategies enhance the robustness and reliability of barcode generation. Thorough input validation, comprehensive error handling, detailed logging, and robust exception management are key. Unit testing and integration testing of the barcode generation process are crucial for identifying and fixing potential problems before deployment. Regular monitoring of the system for errors and performance issues allows for proactive identification and resolution of problems.

Consider incorporating mechanisms for automatic error reporting and recovery, which can significantly improve the overall reliability and user experience. For example, the system could automatically retry failed barcode generation attempts a limited number of times before notifying the user.

Future Trends in Barcode Technology

Barcode technology, while seemingly mature, is experiencing a renaissance driven by advancements in computing power and the rise of interconnected systems. We’re moving beyond simple inventory tracking to a world where barcodes play a crucial role in supply chain optimization, product authentication, and even personalized experiences. The convergence of several technologies is reshaping the future of this seemingly ubiquitous technology.The integration of emerging technologies is dramatically altering the landscape of barcode generation and usage.

We’re seeing a significant shift toward more sophisticated applications, driven by the need for increased security, improved data management, and enhanced traceability throughout the product lifecycle. This evolution is impacting not only how barcodes are created but also how they are interpreted and utilized across various industries.

AI-Powered Barcode Analysis and Generation

Artificial intelligence is revolutionizing barcode technology, moving beyond simple scanning and decoding. AI algorithms can now analyze large datasets of barcode scans to identify trends, predict demand, and optimize inventory management. For instance, a retailer could use AI to analyze barcode scan data to predict which products are likely to sell out and proactively adjust their ordering process. Furthermore, AI can be used to automatically generate barcodes based on product information extracted from various sources, streamlining the barcode creation process significantly.

This automated generation reduces manual errors and speeds up the entire process, leading to greater efficiency.

Blockchain for Enhanced Security and Traceability

Blockchain technology offers a secure and transparent method for tracking products throughout their entire journey, from origin to consumer. By embedding barcode data onto a blockchain, companies can create an immutable record of a product’s history, making it virtually impossible to counterfeit or tamper with. This is particularly beneficial in industries like pharmaceuticals and luxury goods, where counterfeiting is a major concern.

Imagine a luxury handbag with a barcode linked to a blockchain; consumers can scan the barcode to verify its authenticity and trace its entire production history, building trust and combating counterfeiting.

The Rise of 2D Barcodes and Data Capacity

While traditional 1D barcodes remain prevalent, the adoption of 2D barcodes like QR codes and Data Matrix codes is accelerating. These barcodes can store significantly more data than their 1D counterparts, enabling the inclusion of rich product information, multimedia content, and even links to websites. This increased data capacity allows for enhanced consumer engagement and provides opportunities for personalized marketing campaigns.

For example, a QR code on a food product packaging could link to nutritional information, recipes, and even customer reviews, enhancing the consumer experience and fostering brand loyalty.

Improved Barcode Image Optimization Techniques

Advances in image processing techniques are leading to more robust and reliable barcode scanning, even in challenging conditions such as low light or damaged packaging. This is achieved through the development of more sophisticated algorithms that can correct for distortions and noise in barcode images. The improved image optimization contributes to increased accuracy and efficiency in barcode scanning, reducing errors and improving overall data quality.

So, you’re building a barcode generator, right? That’s cool! But have you thought about how you could integrate that with an applicant tracking system to streamline your application process? Imagine using barcodes to track applications throughout the whole system – way more efficient than spreadsheets, right? Then you can use your barcode generator to create unique identifiers for each applicant.

This is particularly important in automated systems where high-throughput barcode scanning is critical.

Impact on Various Industries

The advancements in barcode technology are transforming various industries. In healthcare, barcodes are used for patient identification, medication tracking, and inventory management, improving patient safety and operational efficiency. In logistics, barcodes enable real-time tracking of shipments, optimizing delivery routes and reducing delays. In manufacturing, barcodes streamline production processes, improving quality control and reducing waste. The ongoing development and integration of these technologies will only further enhance the role of barcodes in these and other industries, contributing to improved efficiency, security, and consumer experiences.

Final Summary

From the simple UPC-A on your cereal box to the complex QR codes on your concert tickets, barcode generators are everywhere, silently powering efficiency and accuracy across countless industries. Understanding their inner workings, from the choice of symbology to the integration with databases and APIs, is crucial for anyone working with data management, logistics, or retail. We hope this exploration has given you a new appreciation for the power and versatility of barcode technology, and inspired you to explore its possibilities further.

General Inquiries

Can I create barcodes without any special software?

Totally! Many free online barcode generators exist, though dedicated software offers more advanced features.

What’s the difference between a UPC and a EAN barcode?

UPC (Universal Product Code) is primarily used in North America, while EAN (European Article Number) is the international standard. EAN-13 is the most common type and is compatible with UPC scanners.

Are there any legal restrictions on using barcode generators?

Yes, you generally need to obtain a GTIN (Global Trade Item Number) for certain barcode symbologies like UPC and EAN. The requirements vary depending on your location and industry.

How do I choose the right barcode symbology for my needs?

Consider factors like the amount of data you need to encode, the required scan distance, and the type of scanner you’ll be using. Some symbologies are better suited for specific applications.

What if my barcode doesn’t scan correctly?

Double-check the data input for errors, ensure the image quality is high enough, and verify that the barcode is properly aligned and not damaged.