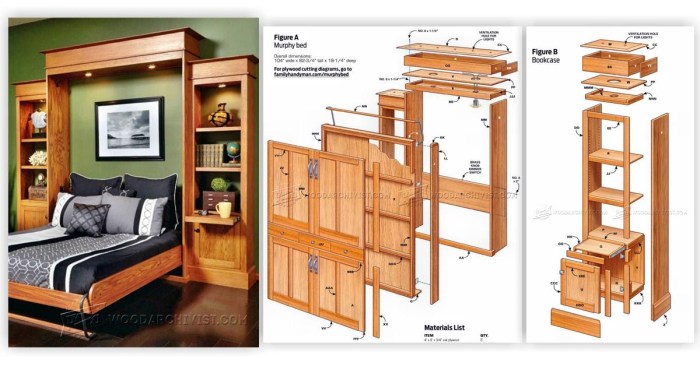

DIY Queen Murphy Bed sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality from the outset. This comprehensive guide delves into the world of creating your own custom Murphy bed, a space-saving marvel that transforms any room into a functional and stylish haven.

From planning and design to construction and customization, we’ll explore every step of the process, empowering you to build a Murphy bed that perfectly complements your home and lifestyle. Discover the advantages of building your own Murphy bed, including cost savings, personalized design, and the satisfaction of crafting a unique piece of furniture.

Building the Murphy Bed Frame: Diy Queen Murphy Bed

The frame of your DIY Murphy bed is the foundation of your project, providing the sturdy structure that will support the mattress and allow it to fold up seamlessly. It’s crucial to get the measurements right and choose the appropriate wood for a reliable and durable bed.

Cutting and Assembling the Wood

Cutting and assembling the wood for the Murphy bed frame requires precision and attention to detail. You’ll need to cut the wood to specific lengths and angles, ensuring that everything fits together perfectly. This involves using a variety of tools, including a circular saw, miter saw, and drill.

For accurate cuts, use a miter saw or a circular saw with a guide. Ensure you’re using a sharp blade and make test cuts on scrap wood to adjust the blade depth and angle as needed.

- Measure and mark the wood for each frame piece, ensuring all cuts are precise and accurate.

- Use a circular saw or miter saw to cut the wood according to your markings. Double-check your measurements and ensure the cuts are clean and straight.

- Assemble the frame using wood glue and screws. Start by assembling the main frame, followed by the supporting frame for the mattress.

- Use a drill to create pilot holes for the screws to prevent splitting the wood. Drive the screws in securely to ensure the frame is strong and stable.

- Reinforce the frame by adding additional supports or bracing as needed. Consider using wood cleats or metal brackets to enhance stability.

Attaching the Hinges and Hardware

Once the frame is assembled, it’s time to attach the hinges and hardware for the bed mechanism. This is a crucial step, as it will determine how smoothly the bed folds up and down.

- Choose the right type of hinges for your Murphy bed. Consider the weight of the mattress and the frequency of use when selecting hinges.

- Measure and mark the positions for the hinges on the frame and the bed platform. Ensure the hinges are aligned and spaced evenly.

- Use a drill to create pilot holes for the hinge screws, preventing splitting the wood. Attach the hinges securely to the frame and bed platform.

- Install the bed mechanism hardware according to the manufacturer’s instructions. This typically involves attaching brackets and supports to the wall and frame.

- Test the bed mechanism to ensure it operates smoothly and the bed folds up and down without any resistance. Make any necessary adjustments to the hinges or hardware.

Frame Measurements

The following table Artikels the necessary measurements for each part of the Murphy bed frame. These measurements are based on a standard twin-sized bed and may need to be adjusted for different bed sizes.

| Part | Length | Width | Quantity |

|---|---|---|---|

| Main Frame Top | 80 inches | 40 inches | 1 |

| Main Frame Bottom | 80 inches | 40 inches | 1 |

| Main Frame Sides | 40 inches | 10 inches | 2 |

| Bed Platform Top | 78 inches | 38 inches | 1 |

| Bed Platform Bottom | 78 inches | 38 inches | 1 |

| Bed Platform Sides | 38 inches | 10 inches | 2 |

Safety and Stability

A sturdy and stable Murphy bed is crucial for both safety and peace of mind. It’s important to ensure that the bed can safely support the weight of a person or people sleeping on it, without any risk of collapsing or malfunctioning. This section will provide guidance on how to achieve this, focusing on material selection, hardware usage, and stability testing.

Testing the Bed’s Stability and Weight Capacity

It is essential to thoroughly test the bed’s stability and weight capacity before using it. This involves simulating the weight and movement of a person sleeping on the bed.

Here’s how to test the bed’s stability:

- Static Load Test: Place a weight equivalent to the maximum intended user weight on the bed’s sleeping surface. The bed should not sag or show any signs of strain under this weight.

- Dynamic Load Test: Gently move the bed up and down, simulating the movement of someone getting in and out of bed. Ensure that the bed remains stable and secure throughout the movement.

- Safety Factor: Aim for a safety factor of at least 2. This means the bed should be designed to handle at least twice the weight of the heaviest person using it.

Important Note: Always conduct stability and weight capacity tests before using the Murphy bed. It is crucial to ensure that the bed can handle the weight of the intended users without any risk of collapse.

Budgeting and Cost Considerations

Building a DIY Murphy bed can be a rewarding project, but it’s crucial to factor in the costs involved. By carefully planning and budgeting, you can make the most of your investment and ensure a successful build.

Estimating Material Costs

To accurately estimate the cost of your Murphy bed project, consider the following:

- Wood: This is the primary material, and prices vary depending on wood type, thickness, and quality. For a sturdy frame, consider using plywood or solid wood like pine or maple. Estimate the cost based on the dimensions and quantity of wood required.

- Hardware: Hinges, brackets, screws, and other hardware are essential for assembling the bed. Research prices for different types and ensure you have enough for all connections.

- Support Mechanisms: Depending on your design, you might need gas struts, springs, or other support mechanisms to assist with lifting and lowering the bed. Research and compare prices for suitable options.

- Finishing Materials: Consider the cost of paint, stain, or other finishes to achieve your desired aesthetic. Factor in the amount needed for the entire project.

Finding Affordable Materials, Diy queen murphy bed

- Check Local Lumber Yards: Local lumber yards often offer competitive prices and may have sales or discounts on specific wood types. Ask about clearance items or remnants that can save you money.

- Visit Discount Stores: Home improvement stores like Home Depot or Lowe’s often have sales and clearance sections where you can find affordable materials. Be sure to compare prices and quality before purchasing.

- Consider Second-Hand Options: Check local flea markets, thrift stores, or online marketplaces for used wood or hardware. This can significantly reduce your costs, but ensure the materials are in good condition and suitable for your project.

Maximizing Value for Money

- Plan Efficiently: Carefully measure and plan your design to minimize waste and ensure you buy the right amount of materials. Avoid overbuying, which can lead to unnecessary expenses.

- Prioritize Quality: While it’s tempting to save money on cheaper materials, investing in quality wood and hardware can make a difference in the long run. This ensures your bed is sturdy and durable.

- Consider DIY Alternatives: Explore options like building your own support mechanisms or using readily available items like PVC pipes for framing. This can significantly reduce your reliance on expensive pre-made components.

Cost Savings Compared to Pre-Made Beds

- Significant Savings: DIY Murphy beds can save you a considerable amount of money compared to purchasing a pre-made option. This is because you eliminate the markup and labor costs associated with manufactured furniture.

- Customization: Building your own bed allows you to customize it to your specific needs and preferences. You can choose the size, materials, and features that best suit your space and budget.

Embark on this DIY adventure and unlock the potential of your space with a custom-built Murphy bed. With careful planning, attention to detail, and a touch of creativity, you can transform your dreams into reality, creating a functional and stylish centerpiece for your home. Let the journey begin!

Building a DIY queen Murphy bed can be a fun and rewarding project, but it can also be a bit overwhelming. If you’re looking for a way to add a touch of whimsy to your project, consider adding some pom poms to the headboard or footboard. You can easily make your own pom poms with a simple DIY pom pom maker , and they’ll add a pop of color and texture to your bed.

Once you’ve finished your pom poms, you can get back to tackling the bigger project of building your queen Murphy bed!